From Tracks to Rollers: Exploring a Wide Variety of Komatsu Undercarriage Parts

From Tracks to Rollers: Exploring a Wide Variety of Komatsu Undercarriage Parts

Blog Article

Increase Productivity With Undercarriage Components and Its Makes Use Of

Recognizing the detailed elements that comprise the undercarriage of heavy machinery is crucial for companies aiming to enhance their functional performance. From track footwear to gears and idlers, undercarriage components play a crucial role in the performance and long life of devices. The critical utilization of these elements can lead to considerable improvements in efficiency and cost financial savings. Let's discover how businesses can harness the power of undercarriage parts to enhance their procedures and drive success in an open market.

Importance of Undercarriage Parts

Routine upkeep and prompt substitute of undercarriage parts are essential to avoid expensive downtime and optimize efficiency. Worn-out undercarriage elements can cause decreased traction, boosted fuel consumption, and sped up endure other components of the equipment. By spending in top notch undercarriage components and sticking to a stringent upkeep schedule, operators can maximize the efficiency of their heavy equipment and extend its solution life.

Common Kinds of Undercarriage Components

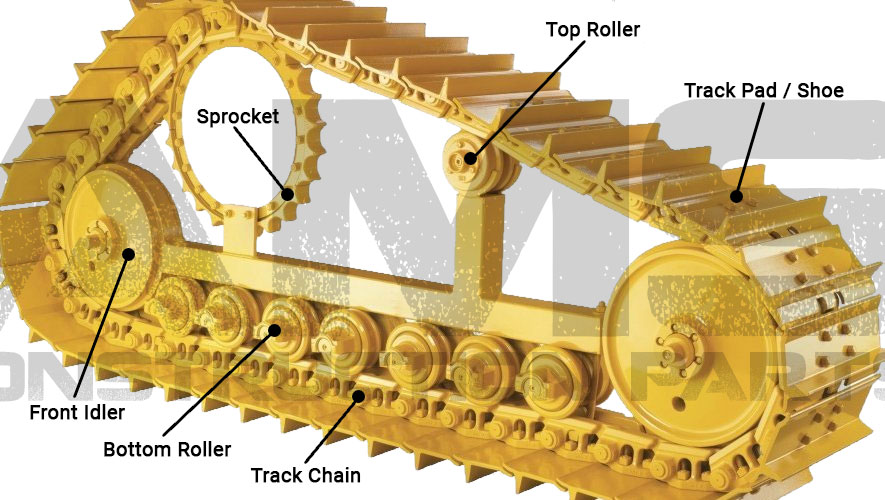

Important components essential for the reliable operation of heavy equipment, undercarriage components play a crucial role in ensuring optimum performance and long life of the devices. Some usual kinds of undercarriage components include track chains, track footwear, rollers, idlers, sprockets, and track frames. Recognizing the feature and value of these typical undercarriage parts is vital for keeping hefty equipment in optimal working condition, decreasing downtime, and making the most of efficiency on task websites.

Advantages of Routine Upkeep

Enhancing functional effectiveness and extending devices life-span, routine maintenance of undercarriage components is essential for maximizing hefty machinery performance. By adhering to a structured upkeep routine, operators can prevent costly break downs and lessen downtime. Normal evaluations and maintenance of undercarriage parts such as tracks, rollers, gears, and idlers not only make certain smooth operation yet also contribute to total description safety on task websites.

Enhancing Tools Performance

Additionally, selecting the appropriate undercarriage parts for particular operating conditions is vital. Variables such as the kind of terrain, workload, and environmental read the full info here conditions should be taken into account when selecting undercarriage parts. Making use of top notch parts that are made to withstand the demands of the task can enhance total tools performance and longevity.

Moreover, keeping undercarriage parts well-lubricated and tidy is vital for smooth procedure. Dirt, particles, and lack of lubrication can cause early deterioration on elements, leading to minimized performance and prospective breakdowns. Normal cleaning and lubrication routines can assist stop these concerns and make sure consistent devices performance.

Cost-efficient Solutions for Organizations

To optimize undercarriage parts effectively and ensure lasting equipment efficiency, companies need to prioritize cost-efficient solutions that line up with their operational needs and spending plan restrictions (komatsu undercarriage parts). Spending in top quality undercarriage components can lead to substantial cost savings in the long run by minimizing downtime, upkeep prices, and the danger of unexpected tools failings.

Furthermore, services can explore alternate undercarriage components such as aftermarket elements that fulfill sector criteria and specifications at a reduced cost than OEM parts. By carefully assessing their options and partnering with trusted suppliers, businesses can efficiently manage their undercarriage component expenses without compromising on performance or reliability.

Conclusion

In conclusion, undercarriage parts play a vital function in improving tools performance and efficiency. It is clear that undercarriage components are important parts for companies looking to enhance efficiency and maintain their devices in optimum problem.

From track shoes to idlers and sprockets, undercarriage components play a vital role in the performance and longevity of devices.The value of undercarriage components in hefty equipment can not be overemphasized, as they are important components that substantially influence the general efficiency and longevity of the tools.Crucial parts vital for the efficient operation of heavy useful reference equipment, undercarriage parts play a crucial duty in ensuring ideal performance and longevity of the equipment.Enhancing functional efficiency and lengthening tools life expectancy, regular maintenance of undercarriage components is crucial for taking full advantage of hefty equipment efficiency. In addition, services can check out alternate undercarriage parts such as aftermarket components that fulfill market requirements and specs at a reduced cost than OEM components.

Report this page